Pflitsch Floor Trunking - cable trunking

- PFLITSCH Floor Trunking is an advanced system designed as a response to increased mechanical requirements in industrial environments. It enables modern, reliable, and organised cable routing in areas with heavy pedestrian traffic and loads.

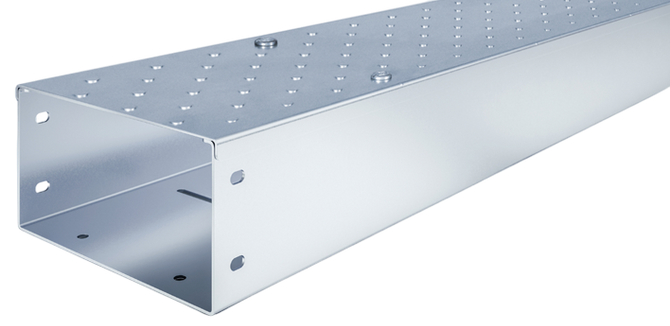

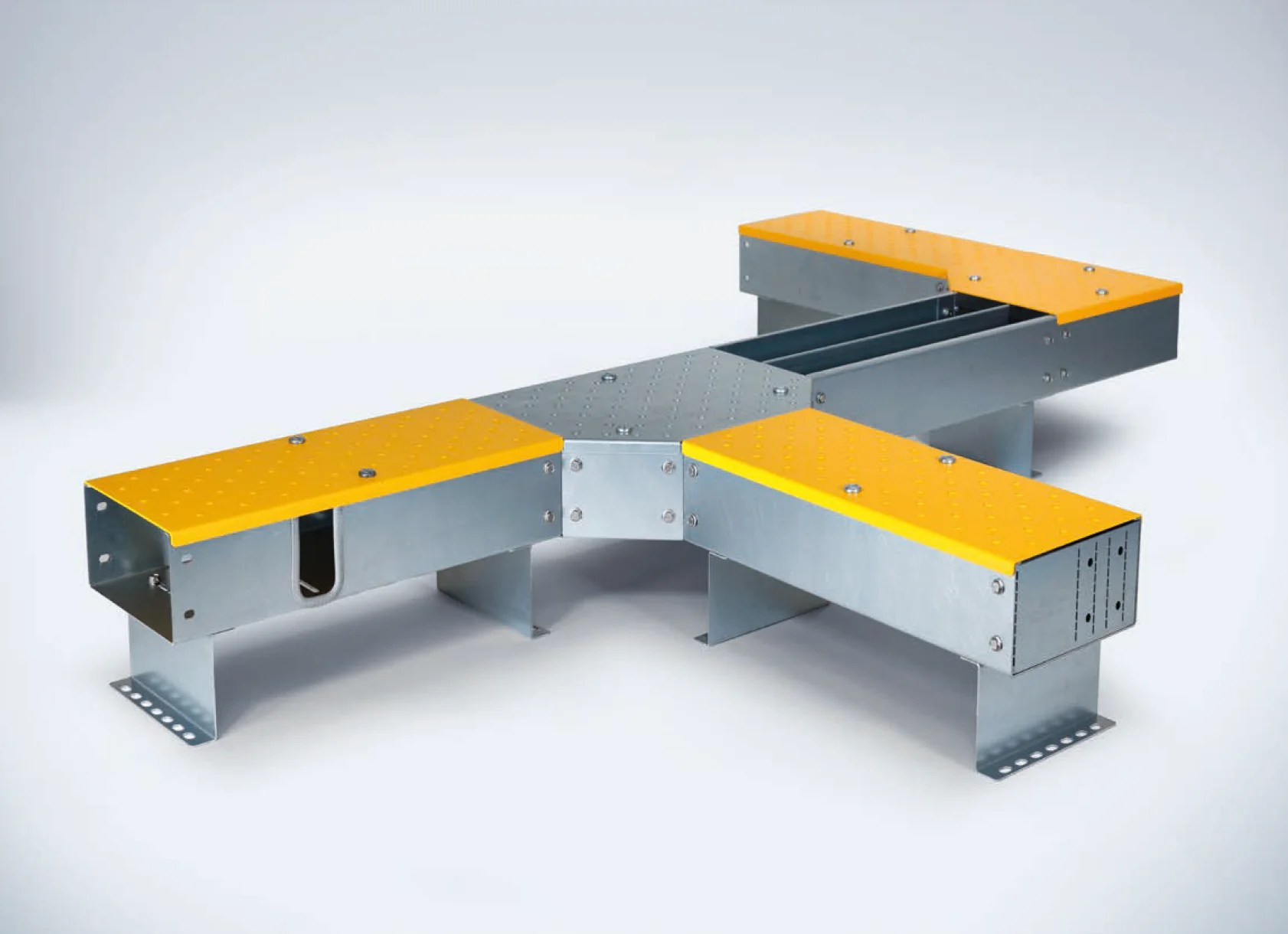

PFLITSCH Floor Trunking is an advanced system designed as a response to increased mechanical requirements in industrial environments. It enables modern, reliable, and organised cable routing in areas with heavy pedestrian traffic and loads. This system constitutes an efficient and economical solution that intelligently combines stability, safety, and efficiency. The PFLITSCH Floor Trunking, thanks to its robust construction and high-quality workmanship, is ideal for applications characterised by high loads and demanding environmental conditions. It is a modular system, available in a wide range of nominal sizes, from 100/100 to 600/100 mm (width/height), made of galvanised steel (S) or optionally galvanised and painted steel (L).

Key Features of PFLITSCH Floor Trunking

Safety of Use

The value of Floor Trunking is based on three pillars: safety, durability, and optimisation of the installation process. Above all, this system guarantees maximum work safety thanks to the use of anti-slip surface. The covers are safe to walk on even with high foot loads and provide slip resistance R10. Available are various cover variants, including those with an embossed anti-slip surface or versions with specialised checker plate, designed for even heavier conditions. An additional design advantage is the increased stability achieved thanks to the new, continuous support feet.

Durability

The floor trunking is made of 2 mm thick galvanised sheet steel, which ensures a perfect fit. Thanks to this, it is characterised by exceptionally high stability. As a result, it easily withstands loads from foot pressure up to 2000 N, and also allows installation with large support distances, which saves time and money during assembly. Thanks to adjustable connecting strips, the floor trunking can be smoothly adapted to inclines from 90° to 180°.

Savings and Optimisation

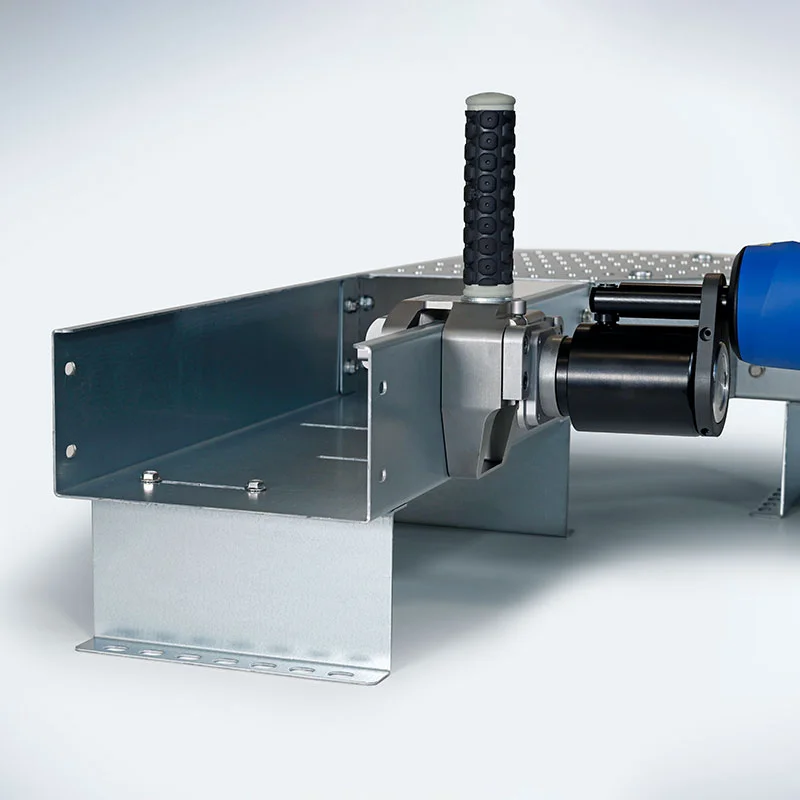

Thanks to the innovative design of the integrated anti-slip embossing, the PFLITSCH solution intelligently reduces the number of required components and simultaneously reduces the labour and costs associated with installation. Moreover, the trunking can be precisely cut and adjusted on-site using special PFLITSCH machines and tools. To achieve maximum efficiency in project execution and minimise potential errors, PFLITSCH can supply the floor trunking as an individually pre-configured, ready-to-install assembly, according to customer specifications. Inside the trunking, it is possible to use adjustable separating profiles that fit the trunking body with system bottom perforation, enabling optimal separation of different cable types.

Certifications

The quality of the solution is confirmed by compliance with commonly used industrial standards, including UL classification according to Nema VE 1-2009 and CSA C22.2 No. 126.1-09.

Areas of Application

The PFLITSCH Floor Trunking system, thanks to its versatility and compatibility with other PFLITSCH systems, is a universal solution for many industries. It is intended for use wherever it is crucial that cables are simultaneously protected, organised, and safely accessible.

- Production lines

- Robot cells

- Machine parks

- Industrial automation

- Machine and plant construction

- Automotive production

It is ideal for:

This solution is chosen when it is necessary to ensure the long service life and lasting load capacity of the cable infrastructure.