FLEXAquick Assembly - quick‑connect mounting of corrugated conduits with IP68 integrity preserved

A traditional connector usually consists of a body, a compression nut, a ring and a seal. First you cut the conduit; then, in the correct order, you slide all parts on, screw the conduit into the body and tighten everything with a torque wrench according to the manufacturer’s table. Each step carries risks: reversed assembly order, a lost O‑ring or too little/too much tightening torque. The result? Leaks, loss of IP65–68 rating, complaints, and the need for laborious disassembly and seal replacement.

The FLEXAquick system reduces the connector to a single housing with a push‑in snap‑lock mechanism. To ensure correct installation, the ROHRflex conduit must first be cut in the groove of its corrugation. Then you simply press the conduit into the fitting. Proper seating is indicated by noticeable resistance when you try to twist the connector.

The whole process eliminates loose nuts, seals and tools. Disassembly is just as simple: press the ring and pull the conduit out. According to the manufacturer, installation takes less than 5 seconds and boosts productivity up to fivefold compared to traditional methods. The result: you make hundreds of connections in the time that previously covered only dozens—while maintaining a consistently high IP rating of 65/66/68/69K.

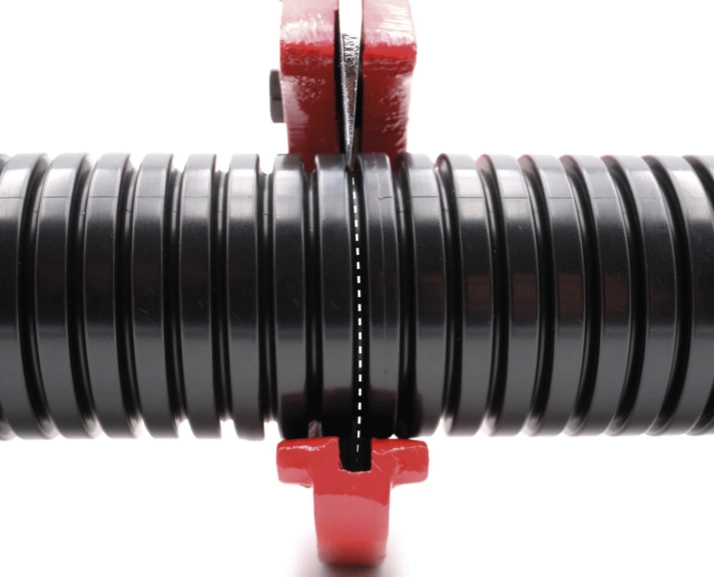

Cutting

To achieve IP68/67/66/65 protection classes in accordance with DIN EN 60529 and ensure correct installation, cut the conduit to the required length beforehand.

Use an appropriate tool (a knife or ROHRflex shears) to cut the ROHRflex corrugated tube straight through the corrugation.

Make sure the cutting edge runs evenly through the trough of the corrugation.

Connecting

Place the connector with the cable entry onto the cut end of the conduit.

Push the connector onto the corrugated conduit until it stops and can only be turned with significant force.

The conduit presses the teeth of the snap sleeve into the grooves of the conduit, locking the connector securely.

Disconnecting

To remove, press the snap sleeve ring towards the connector body.

Then pull the conduit out of the fitting or remove the fitting from the corrugated conduit.

No additional tools are needed for disassembly. The connector can be reused.